|

|

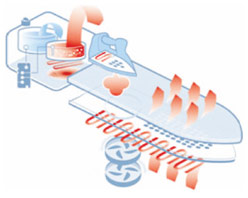

Triovapore System

- Steam a t the tip:

the steam passes through a special chamber and comes out the nozzles at the tip.

- Classic:

the steam is conveyed onto the soleplate only.

- Combined:

the combined action of steam in the soleplate and at the tip smoothes the most difficult fabrics

|

|

|

Energy Saver

The active air circulating system eliminates condensation from the interior of the ironing board surface,

thereby preventing dripping of water. It extracts and dries without the internal heating element,

maintaining the comfort of traditional models. |

|

|

2 Motors

The active three-functions ironing board: suction, ventilation and heated surface, brings further

advantages and adds to the features and the specific plus points of the ironing systems, improving their

performance to obtain an unrivalled result in record titime! |

|

|

Perfect steam emission

- On the left the traditional system, on the right the electronic operating control.

- The electronic control manages the flow of water from the cold water tank to the boiler

- Continuous steam output at high pressure because only the necessary water is heated.

The new, more advanced and precise Electronic Operating System (Perfect Steam Emission) controls and synchronizes the flows, thereby stabilizing the performance. Water input into the tank is carefully regulated – small jets – progressive – continuous jets – and it is immediately heated without waiting for the system to reach working temperature.

The advantages are obvious!

- high steam output

- at high pressure

- and stable during use

( standard/intensive ironing, cleaning)

|

|

|

Unlimited steam supply

Boiler type

Water is heated to boiling point inside the stainless steel pressurized boiler (externally fitted heating element). When reaching working pressure, the steam flow may be controlled by the button on the iron When the steam reaches the iron soleplate, it undergoes a second evaporation at high pressure (steam Chamber).

Auto refill type = unlimited steam supply

Water is conveyed by a pump from an external cold tank, which is sometimes removable, into the stainless steel pressurized boiler, where it is brought up to boiling temperature. A thermostatic level sensor controls the filling with water. Using the control button on the iron, pressurized steam is sent to the soleplate where it undergoes further evaporation (steam chamber), thereby increasing in quality and power.

|

|

|

Integrated active ironing board

In addition to the typical advantages and results of a three-functions ironing board, the version with integrated control unit incorporates all the technical and functional features of an automatic refill boiler with electronic operating control. The professional “ironing station” for home use.

Remote fan control

Remote Fan Control is the control which may be used to start and stop the motors (delayed) in the suction or ventilation mode when required.

|

|